The world of tech evolves at a rapid pace. Here are some recent innovations that are changing the worlds of manufacturing, photonics and transport.

1. Forecasting machine downtime

Engineers from Fraunhofer Society, a German research institute, are collaborating with partners from other research institutes and industry to develop maintenance technology that will forecast machine downtimes before they occur. The system will allow plant and factory managers to correct issues before the machine breaks down, allow systems to keep running even when some faults occur, and correct some defects automatically.

Unforeseen machine failures that occur during the course of production can trigger reactive repairs, drive up costs, affect the ability of factories to deliver results reliably, and ultimately weaken the competitiveness of the organisation. Often, failures are caused by a small defect or normal wear and tear. But small weaknesses in a system, if left undetected, can lead to major disruptions and production downtime.

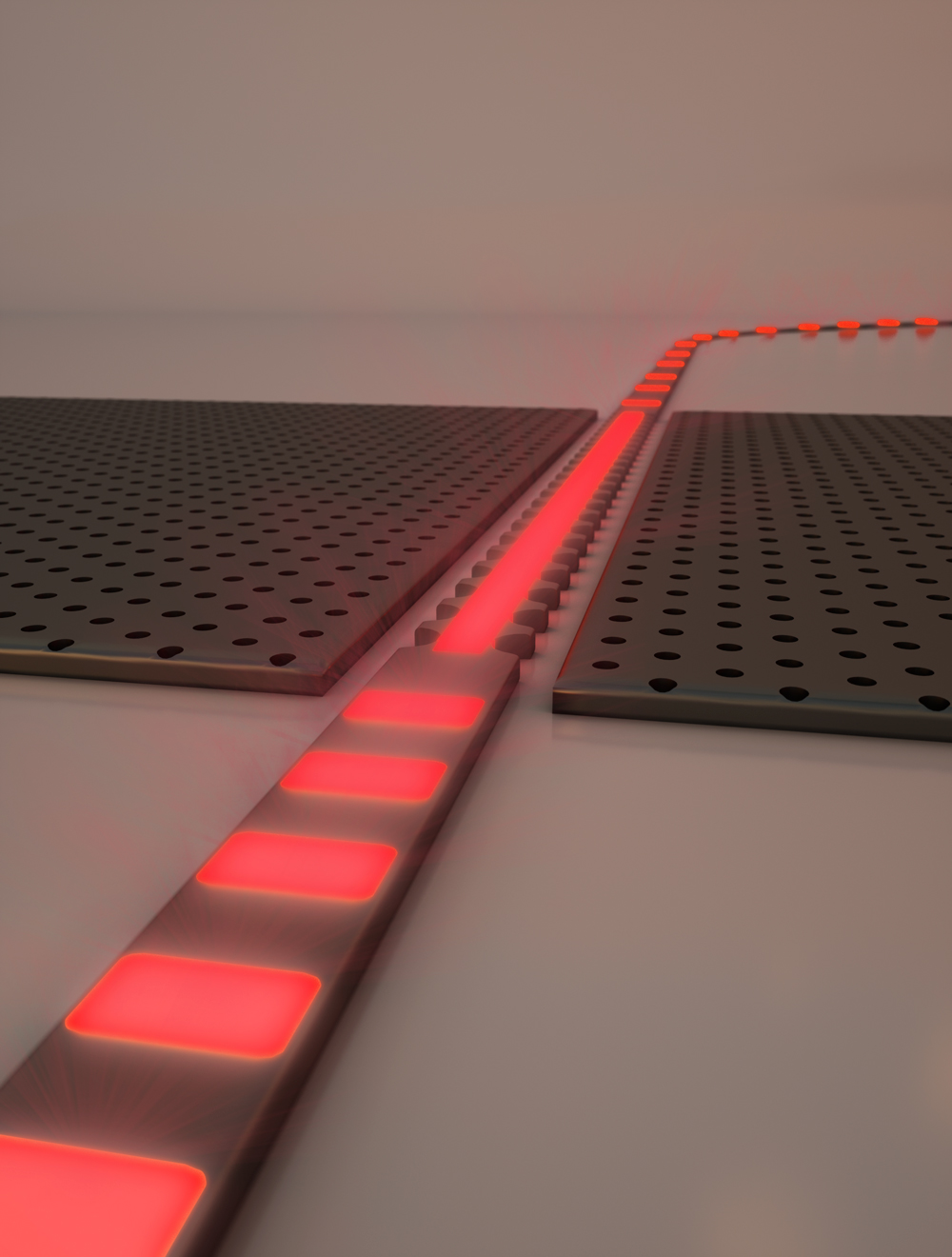

2. Zero-index waveguide

Photonics researchers may soon have another tool to work with the demonstration of a zero-index waveguide compatible with current silicon photonic technologies. A team from the Harvard School of Engineering and Applied Sciences, which previously developed the first on-chip metamaterial with a refractive index of zero, has pushed that technology further with the zero-index waveguide.

When a wavelength of light moves through a material, its crests and troughs get condensed or stretched, depending on the properties of the material. How much the crests of a light wave are condensed is expressed by the refractive index. When the refractive index is reduced to zero the light no longer behaves as a moving wave, traveling through space in a series of crests and troughs, otherwise known as phases. Instead, the wave is stretched infinitely long, creating a constant phase. The phase oscillates only as a variable of time, not space.

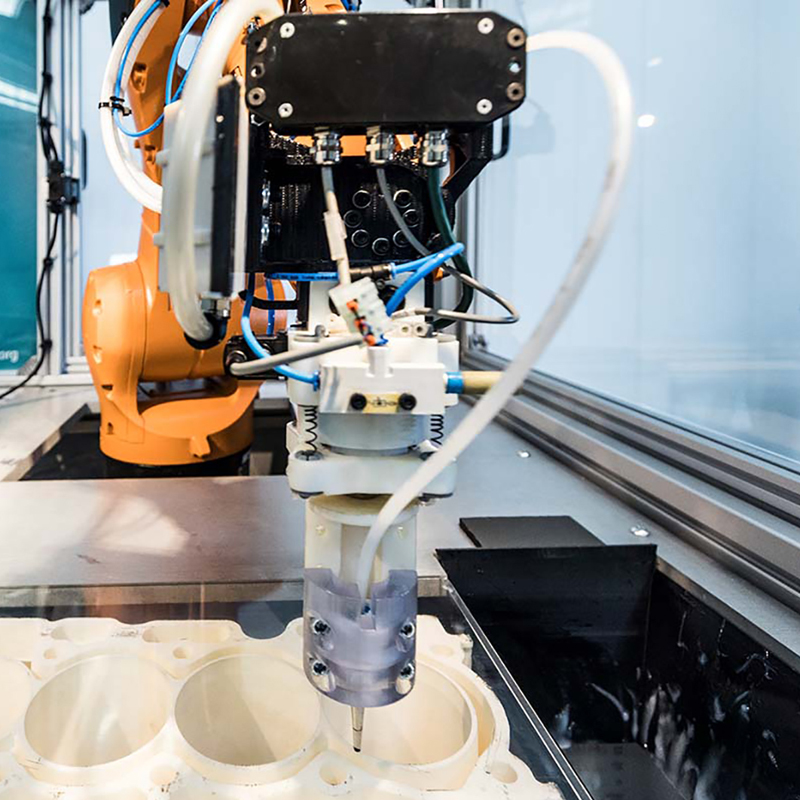

3. Artificial muscle mimics biology

A team from Columbia Engineering in New York City has developed a 3D-printable synthetic soft muscle with intrinsic expansion ability that does not require an external compressor or high voltage equipment as previous muscles required. The new material can lift 1000 times its own weight and has a strain density (expansion per gram) that is 15 times larger than natural muscle.

Existing soft actuator technologies are typically based on pneumatic or hydraulic inflation of elastomer skins that expand when air or liquid is supplied to them. The external compressors and pressure-regulating equipment required for such technologies prevent miniaturisation and the creation of robots that can move and work independently.

To achieve this actuator, the team used a silicone rubber matrix with ethanol distributed throughout in micro-bubbles. The solution combined the elastic properties and extreme volume change attributes of other material systems while also being easy to fabricate, low cost, and made of environmentally safe materials.

After being 3D-printed into the desired shape, the artificial muscle was electrically actuated using a thin resistive wire and low-power (8 V). It was tested in a variety of robotic applications where it showed significant expansion-contraction ability, being capable of expansion up to 900 per cent when electrically heated to 80°C.

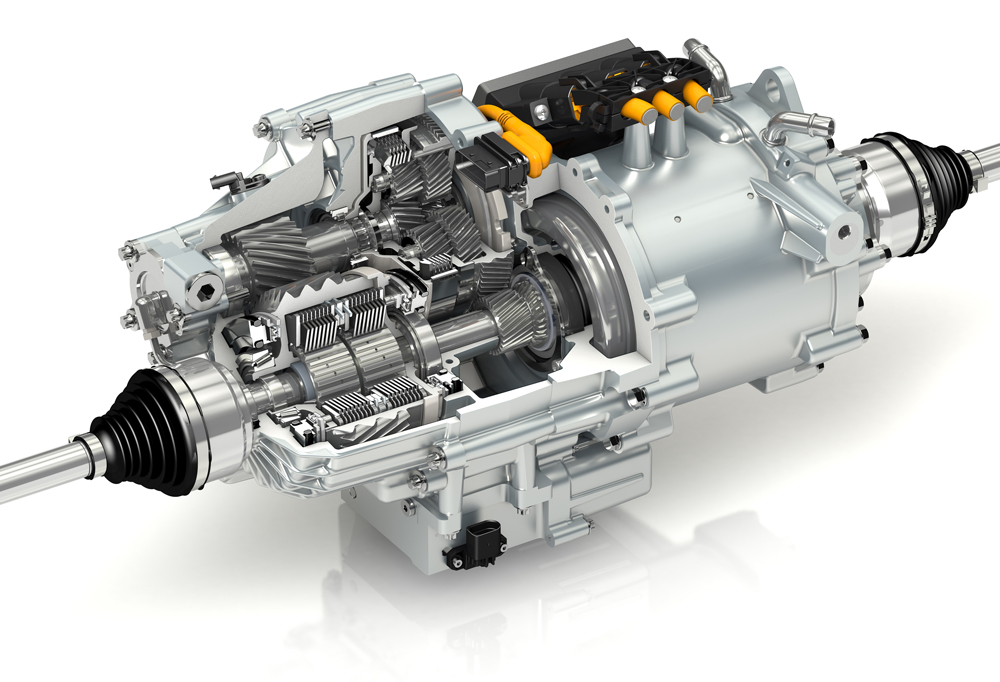

4. Rethinking transmissions

British-based manufacturer GKN Driveline recently unveiled an all-new electric axle concept at the Frankfurt International Motor Show (IAA). Called eTwinsterX, it features an integrated coaxial format meaning that the electric drive (eDrive) unit is significantly smaller than other systems with equivalent power outputs. The system can be used either for the primary drive in fully electric vehicles, or for the secondary drive on plug-in hybrid vehicles, creating a ‘split-axle’ driveline. It employs an all-new two-speed transmission, which enables a better balance of acceleration and top speed than conventional single-speed electric drive units.

Multi-speed transmissions enable electric vehicles to deliver better launch performance, using the lower gear, and more efficient high-speed driving using the higher gear. This strategy keeps the motor operating close to its efficiency ‘sweet spot’, meaning that it can optimise driving range.

Torque vectoring allows for intelligent control of vehicle dynamics by managing the distribution of torque to individual wheels. For example, by enabling over-speeding of the outside wheel in a corner, torque vectoring can induce a yaw-moment, helping to steer the vehicle more safely towards a tighter cornering radius.

It can also produce a negative torque effect to slow the vehicle. When a dynamic imbalance is detected across an axle, the system sends more power to the wheel with the higher traction.

Tech watch is a series where we highlight some of the latest innovations from around the world that flew under the radar. Check back each month for a new batch, or comment below with ones that caught your eye.