Researchers in the US have created a 3D-printed microfluidic device capable of extruding fibres that are one-thousandth the width of a human hair, opening doors for a cheap yet reliable nanofibre mesh industry.

Nanofibre meshes have a variety of uses, including tissue engineering, water filtration and body armour, but to date their production involved etching silicon in an airlocked clean room – a complex and costly process that made mass production impossible.

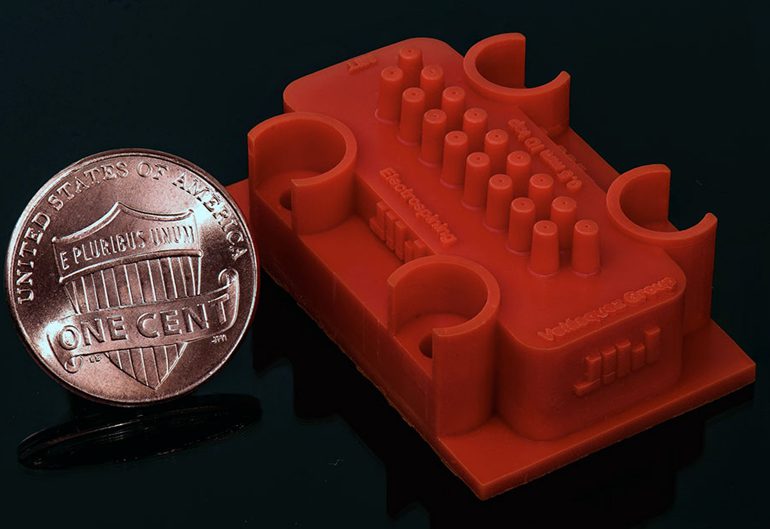

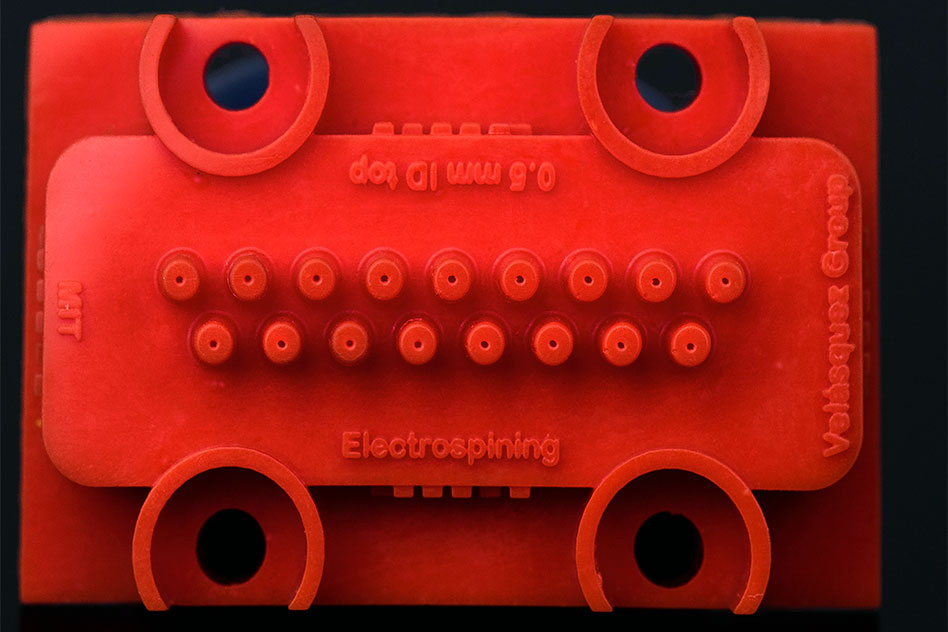

This new 3D-printed device, which is about the size of a LEGO block, streamlines the process and eliminates the fuss by pumping a fluid containing polymer particles through tiny nozzles to produce fibres that are only 75 nanometres in diameter.

It’s a small innovation, but it has big implications. For peak performance, the nanofibre meshes need to maximise surface area in relation to volume, which means the fibres must have consistent diameters to optimise performance.

“The performance of the fibres strongly depends on their diameter. If you have a significant spread, what that really means is that only a small per cent are really working. Example: You have a filter, and the filter has pores between 50 nanometers and 1 micron. That’s really a 1-micron filter,” said lead researcher and study author Luis Velásquez-García.

Velásquez-García, from Massachusetts Institute of Technology’s (MIT) Microsystem Technology Laboratories, added that 3D printing has made it so there is no longer any reason to do microfluidics in a clean room.

“3D printing is a technology that can do it so much better — with better choice of materials, with the possibility to really make the structure that you would like to make. When you go to the clean room, many times you sacrifice the geometry you want to make; and the second problem is that it is incredibly expensive,” he said.

The same research group produced a nanofibre design in 2015 that was etched in a clean room. It was externally fed by using an electric field to draw a polymer solution up the sides of each nozzle. This led to fibres of varying diameters.

Their latest device produces more regular diameters by an internal feeding process where hydraulic pressure forces fluid to fill the nozzles and an electric current then draws the fluid into fibres. The nozzles are fed by gradually tapering channels, which could not be fabricated using previous clean room techniques.

The updated device is also able to produce aligned nanofibres, which are required for applications including tissue scaffolding. This is achieved through configuration of the nozzles in two, slightly offset rows, meaning that nanofibres remain in the same relative position as they are rolled onto a drum.

The device could also be re-engineered with the nozzles in a grid configuration to increase the output rate for applications that can use unaligned fibres.

Using 3D printing has other advantages. According to Velásquez-García, it has allowed his team to reduce the time it takes them to test and revise designs, increasing output from two or three variations over two years to more than 70 iterations in a single year.

Commenting on this innovation, Professor Mark Allen from University of Pennsylvania, who has joint appointments in electrical engineering, systems engineering and mechanical engineering, said this device creates great future opportunities for nanofibre production.

“I anticipate that somebody’s going to take this technology and use it in very creative ways. If you have the need for this type of deterministically engineered fibre network, I think it’s a very elegant way to achieve that goal,” he said.

The 3D printer revolution has also changed the goalposts for manufacturing other previously high-priced products, including custom prosthetics for amputees and next-gen materials such as carbon fibre.